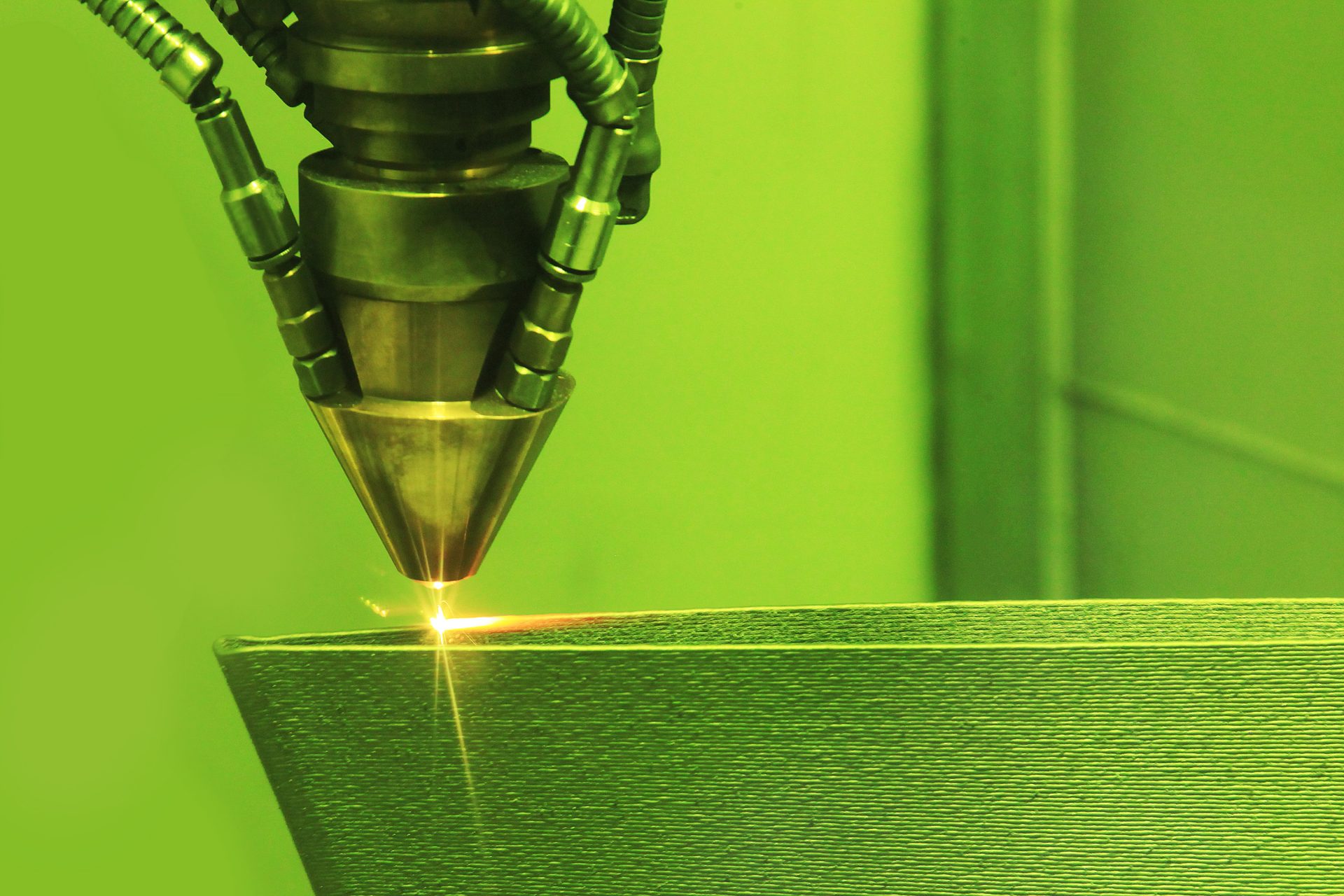

Internet of things

“The first three industrial revolutions came about as a result of mechanization, electricity and IT. Now, the introduction of the Internet of Thingsand Services into the manufacturing environment is ushering in a fourth industrial revolution. In the future, businesses will establish global networks that incorporate their machinery, warehousing systems and production facilities in the shape of Cyber-Physical Systems (CPS). In the manufacturing environment, these Cyber-Physical Systems comprise smart machines, storage systems and production facilities capable of autonomously exchanging information, triggering actions and controlling each other independently.”

[Source: Final report AK Industry 4.0]

Enabler: Wireless connection

Naturally any device in the “Internet of Things” needs a connection. Many of them are wireless. Several are “mission critical” – very important, so the radio contact has to satisfy the strong requirements on availability, latency, and reliability.

Today most of wireless M2M (machine-to-machine) connections are realized by using GSM. This offers several advantages, like a separate, independent company access infrastructure, cheap and proven technology and high compatibility.

However, for several applications is GSM not the best choice. It has lack of bandwidth, reliability, and redundancy. For example, remote access for maintenance and local engineer’s support need higher data rates. Machine control needs higher reliability and much lower latency, it requires almost a real-time support.

Reliability & Redundancy

Brown-iposs helps to ensure reliability and redundancy of wireless access for M2M by fitted solutions. A combination of GSM and Wi-Fi may deliver high data rates and a redundant link in case of the non-availability of either technology. A transmitter without battery may increase reliability and reduces maintenance effort. Using combined gateways with intelligent failover reduces maintenance effort again, and can prevent a new “single-point-of-failure” in the infrastructure.

In any case a precise and careful audit, planning and design of the wireless access network is a mandatory step to avoid unpleasant surprises. Planning of a wireless infrastructure for Industry 4.0 might be a standard Wi-Fi-planning – typically it is not. Instead the deployed infrastructure has to be adapt to the business requirements of the production plant.

Challenge: Security

Another challenge for the “Internet of Things” – and particularly for a wireless access infrastructure – is security. Security has many aspects, like providing access reliability but also ensuring data protection and link integrity. Therefore is an end-to-end encryption of wireless transmitted data is a must-see for all sensible data and is solved mainly on application layer. However link integrity needs a stable and low-interfered physical transmission, but still has to be protected against burst errors. Mission critical links may have to be backed by redundant connections, too.

The experts of brown-iposs are aware of the many aspects wireless M2M solutions have to fulfill in production plants and critical monitoring areas. The many – partially contradicting – requirements of M2M can only be covered by a careful infrastructure planning. With the help of our experience and knowledge we can support our customers to realize the best solution, taking into account costs, efficiency and reliability.